Learn

There's a lot to learn about glass floor systems but it can be incredibly simple to install a beautiful glass floor in your home, or create a wow-factor hinged wine cellar display.

Safety First

Ensuring Secure Glass Flooring

At Glass Floor Systems, safety is our top priority. All our glass floors, including hinged wine cellar doors, are made with toughened and laminated safety glass, meeting a minimum thickness of 25.5mm for domestic use when supported on all four edges. Our hinged and fixed steel frameworks are fully certified to BS 1090-2, while the glass is engineered and tested to withstand a minimum concentrated load of 2.0kN, compliant with BS EN 1991-1-1 2002 standards. For projects requiring building control approval, we recommend consulting your local authority to ensure our products meet your specific needs.

HINGED GLASS WINE CELLAR DOORS

-

About

We refined our hinged glass floor system over several months, perfecting prototypes to create a final design that has become highly sought after. This glass floor system is delivered as a fully assembled unit, requiring minimal installation—simply prepare the space below and customize the racking to your preference. -

Custom Wine Cellar Doors

We supply our hinged glass wine cellar system in a variety of 'standard' sizes available to buy online, or contact us for a bespoke service.

-

Made To Order Glass Doors

Every hinged floor unit is custom-made to order in our Sheffield workshop, utilizing locally sourced materials. As a bespoke product, each unit requires approximately 6 weeks for construction. The structural glass, being notably heavy, is equipped with gas strut mechanisms to facilitate smooth opening and closing, securing the unit in an open position at approximately 85 degrees.

Glass Wine Cellar Doors

-

Manual vs. Electric Systems

Our hinged floor systems are designed for effortless access, regardless of the size and weight of the glass. For a manual hinged floor system, we use precision-calibrated gas struts that provide an assisted lift, ensuring the door is easy to open and holds securely in the raised position.

For the ultimate in convenience, our electric hinged systems feature a discreet motorized mechanism that allows for hands-free operation at the touch of a button (or remote control), providing a seamless and high-tech solution.

-

What Our Systems Include

When you order a hinged glass floor door, we provide a complete, fully assembled unit designed to fit your structural opening. This includes the walk-on safety glass panel and the robust steel frame with all necessary operational mechanisms.

It is important to note that our supply covers the door system itself; the preparation of the floor recess or the work within the space below—such as building a staircase or a wine cellar—is the responsibility of the client or their appointed builder.

-

Customisation & Bespoke Solutions

Beyond our standard rectangular hatches, we specialise in producing custom hinged floor systems to meet any design specification. Whether you require an odd shape, a particularly large system, or a multi-panel solution, we can help.

We can design and manufacture a hinged door with adjoining fixed glass panels or even a series of doors side-by-side to cover a larger floor area. We provide bespoke solutions that are engineered to your exact requirements.

Glass Wine Cellar Doors (Continued)

-

Certification & Structural Integrity

Our hinged glass floor systems are built to the highest safety and quality standards. Each unit is fully certified to BS EN 1090, ensuring the steel framework meets strict structural requirements. The glass panels are composed of toughened and laminated safety glass, designed to withstand significant weight. This rigorous engineering and third-party certification guarantee the integrity of your floor system, providing you with complete peace of mind.

-

Seamless Installation Process

We take the complexity out of installation. All of our hinged glass floor doors are delivered as fully assembled, single units, meaning the frame, glass, and all operational components are pre-fitted in our workshop. For manual systems, this means simply securing the perimeter frame into your floor opening. For electric units, the system arrives with a simple plug-and-play control box, allowing any competent tradesperson to install the unit without needing a specialist electrician.

-

Custom Finishes & Glass Options

Personalise your system to perfectly match your space. Our steel frames are available in a standard durable powder-coated finish, but can also be supplied galvanized for outdoor or high-moisture environments. The glass itself can be tailored with our invisible anti-slip coating for safety in high-traffic areas. Additionally, we offer custom borders—either painted black finish or an alternate RAL colour as preferred—to enhance the aesthetic and create a truly bespoke product.

Glass Well Covers

-

What Our Glass Well Covers Are

Our glass well covers are a safe and elegant way to transform a forgotten water well into a stunning walk-on feature. Handcrafted from toughened and laminated safety glass, each cover is custom-made to a circular design. By creating a visually striking window into your property's history, they allow you to safely reclaim a part of your space while adding a unique architectural element to your home.

-

Bespoke Glass Thickness Options

We offer our glass well covers in two tailored thicknesses to suit your specific diameter and project needs. The 25.5mm thickness, composed of two 12mm panes, is ideal for most standard sizes. For larger diameters, we recommend our 33mm thickness, which uses three 10mm panes, providing enhanced durability and structural support to ensure your well cover is both beautiful and robust.

-

Frame & Non-Destructive Installation

The installation of our well covers is designed to be simple and non-destructive to your existing flooring. Each unit comes with a robust steel support framework that is permanently installed to sit neatly over your well's opening. This allows you to lay your flooring right up to the edge of the frame, ensuring a flush and seamless finish without the need for extensive structural work.

Glass Well Covers (Continued)

-

Advanced Safety Features

Safety is paramount, and our well covers include advanced features for your peace of mind. The glass is treated with an invisible anti-slip coating that provides superior grip and lasting protection. Additionally, the underside of the glass features a special coating to minimize condensation and mould, ensuring a clear view into your well while maintaining a hygienic finish.

-

Structural Integrity & Certification

Every glass well cover is built to strict safety and structural standards. Each unit is UKCA certified and engineered to withstand a 2.0kN concentrated load and 1.5kN/m² uniform load as per industry regulations. This rigorous engineering, coupled with the durable, powder-coated or galvanized steel frame, guarantees that your well cover is not just aesthetically pleasing but also structurally sound and completely safe.

-

Our Simple Ordering Process

Ordering a glass well cover is straightforward, even though each one is custom-made. Simply select the size band that corresponds to your required diameter and place your order. Our team will then be in touch to obtain the exact dimensions of your well's opening. We will provide a detailed technical drawing for your approval before manufacturing begins, ensuring a perfect, tailored fit for your property.

What Thickness of Glass?

Elevate your space with our premium hinged wine cellar doors, glass well covers, and other glass floor products, featuring structural glass floor panels in 25.5mm and 33mm thicknesses, all made from toughened and laminated safety glass.

But which thickness is right for you?

For standard domestic applications, glass floor panels up to 1000 x 1000mm, supported 50mm on all edges, perform reliably with our 25.5mm thick glass. Some choose thicker options for extra peace of mind, especially in high-risk areas like kitchens where dropped pots or pans are a concern—our 33mm thick glass with double lamination (three panes instead of two) is often ideal here.

For commercial use or wider glass spans, thicker glass is typically required. However, to ensure compliance with local regulations, always consult your building control authority when unsure.

Discover our range of glass floor solutions, including custom hinged wine cellar doors and glass well covers, at glassfloorsystems.co.uk!

Non-Slip Glass Flooring

Enhance Safety with Anti-Slip Treatment.

At Glass Floor Systems, we offer an optional anti-slip treatment for your walk-on glass floors, including hinged wine cellar doors and glass well covers to minimize slip risks on their naturally smooth, polished surface.

How Our Anti-Slip Treatment Works

Unlike a traditional coating, our anti-slip glass treatment involves a chemical process that gently removes a small amount of silica from the glass surface, creating microscopic pin holes. These pin holes act as a vacuum underfoot, boosting grip without altering the glass’s transparent appearance—completely invisible to the eye.

Durability and Maintenance

Since it’s not a coating, the treatment won’t wear off, but with moderate use, the pin holes may gradually refill over time, reducing effectiveness. We estimate a lifespan of approximately 5 years under typical conditions. The glass can be retreated as needed to restore its non-slip properties

Glass Floor Design Considerations

-

Likelihood of wet footwear

Where floor glass is placed near doors, or externally, consideration should be given to the potential for slips and trips.

-

Support System

Floor glass is always designed to be supported on its edges, never in the middle. Consider a steel support framework, or have a structural engineer calculate the deflection on other materials (timber joists for example)

-

Concentrated Point Loading

Will the floor glass be used in areas with tables, chairs, castors? Concentrated loads with small contact areas are to be avoided.

-

Uniformly Distributed Loads (UDL)

UDL values will vary between applications and will determine the glass thickness required. Care should be taken to specify the correct figure from EN 1991-1-1-1.

-

Surface Finish

Walk on floor glass can be supplied as a standard flat finish, chemically non-slip treated or with a number of 'frit' patterns sandblasted into the surface

-

Modesty

Standard floor glass is transparent and modesty should be considered when persons can access beneath the glass. Frosted glass could be used to increase privacy.

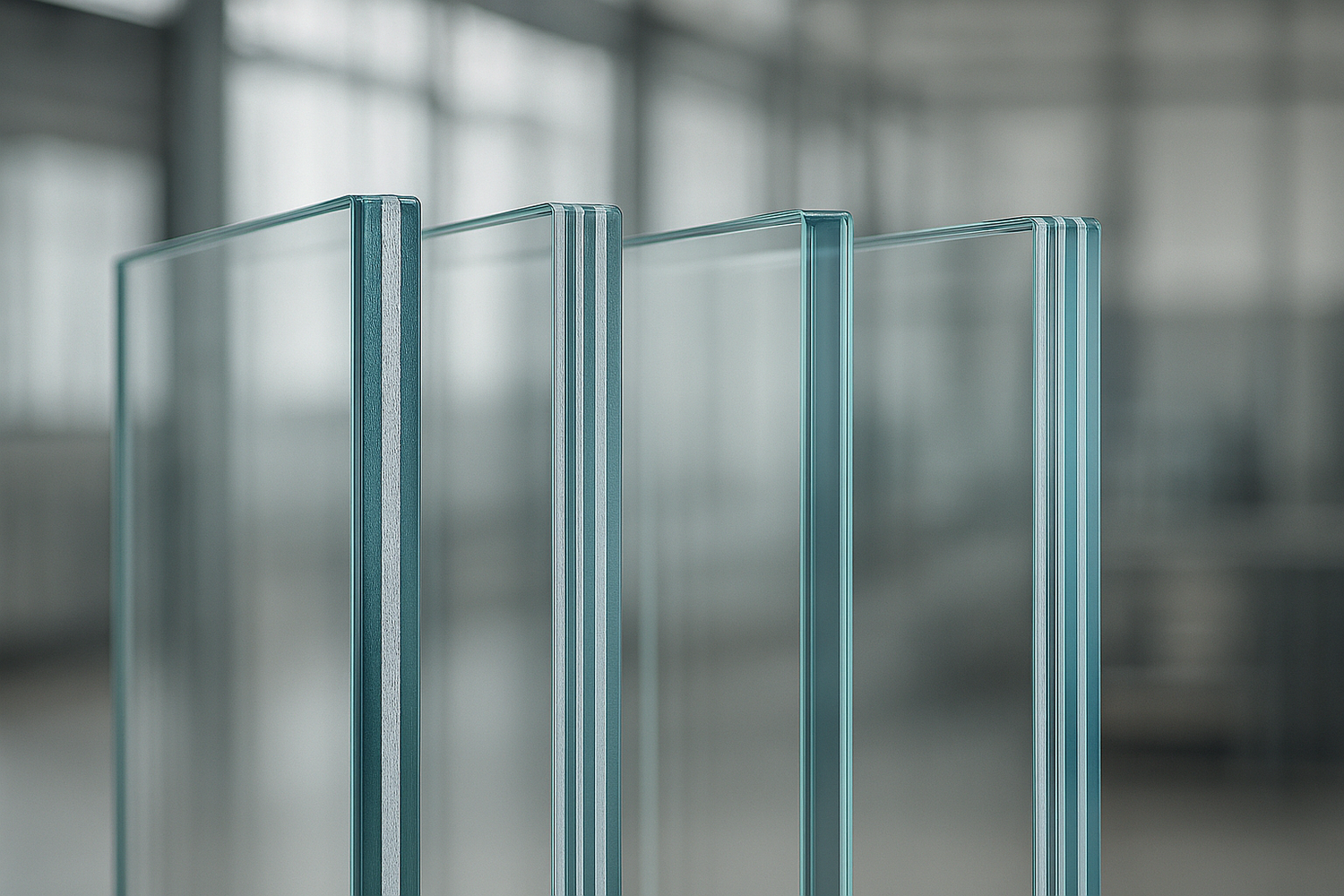

Toughened & Laminated Glass

What is toughened glass?

Also known as tempered glass, toughened glass is upto 5 times stronger than regular glass. The toughening process heats the glass to around 650 degrees Celsius and is then quickly cooled. Toughened glass then becomes, well, tougher than standard glass and is more resilient to heat and shock than ordinary glass.

All our glass is toughened as standard.

What is laminated glass?

Laminated glass can essentially be described as two panes of glass that are laminated (or glued) together. The laminate interlayer is a sheet of plastic that bonds the two sheets together and acts to hold the panes together, if one pane of glass were to break.

Laminated glass is therefore much safer than standard glass. All our floor glass is both toughened and laminated.

Design of floor glass

Walk on floor glass should be designed in such a way that if one panel were to break, the remaining panel would have sufficient strength to continue to provide a safe level of guarding. Typically this therefore requires a minimum glass thickness of 25.5mm, comprising 2no. panes of 12mm toughened glass with a 1.5mm thick laminate interlayer and even thicker glass for large spans.

General Glass Floor FAQs

-

How can I get a quote?

Our walk on floor glass prices are available online in many sizes, or contact us for a bespoke size.

-

What are your lead times?

Lead times will vary dependant on your order specifics and options chosen- individual lead times can be found on each product page.

-

Can I collect?

You are more than welcome to collect from our premises in Sheffield, once your order is ready.

-

What are your payment options?

You can pay by PayPal, all major debit and credit cards or by bank transfer. You can also send a cheque, or pay cash at our premises.

-

Do you have a showroom?

Not yet- but we're working on it..... You are however more than welcome to visit our premises, see samples and discuss your project.

-

Why is your glass so much cheaper than others?

We supply several tonnes of glass throughout the UK on a monthly basis to the commercial industry and residential markets. Large buying power savings for raw material is passed to you, the end consumer.

-

Can I use glass outside?

All our Floor glass laminate interlayers are EVA (not PVB) meaning they are suitable for both internal or external applications.

-

Is floor glass easy to clean?

Certainly- walk on floor glass can be cleaned like any other glass surface or window panel, it can even power washed if you so wish.

-

How safe is floor glass?

So long as you choose a thickness of glass appropriate to the application and install correctly, glass floors are as safe as concrete floors.

General Maintenance

-

Routine Cleaning for a Pristine Finish

Our glass floor systems are designed for minimal maintenance. Much like a high-quality surface in your home, regular cleaning is all that's needed to keep it looking pristine. For the glass, simply use a standard glass cleaner and a microfiber cloth. Avoid abrasive cleaners or scouring pads, as these can scratch the glass or damage the anti-slip coating. Regular, gentle cleaning will ensure your glass floor or hatch remains a clear and stunning feature for years to come.

-

Protecting Your Glass from Damage

While our walk-on glass is incredibly strong, its surface should be treated with care—much like a white carpet. To prevent scratches and damage, avoid dragging heavy or sharp objects across the surface. We recommend not walking over glass in external shoes, but where unavoidable at least a quick check of shoe soles for any grit or stones before walking on the glass. By being mindful of the surface and its purpose, you can preserve the glass’s immaculate finish, ensuring it remains as clear and unblemished as the day it was installed.

-

Frame, Seals, and Longevity

The steel framework and seals of your glass system are engineered for durability. The powder-coated or galvanized finish is highly resistant to corrosion and wear, requiring no special maintenance. Simply wipe it clean as needed. The glass is silicone-sealed into the frame for a secure, long-lasting fit. While these seals are incredibly durable, we recommend a simple visual inspection every couple of years to ensure the integrity of the sealant remains intact.

Painting Glass Borders

At Glass Floor Systems Ltd, we always strongly recommend incorporating a painted glass border on any glass flooring product—whether it’s a hinged wine cellar glass floor, a fixed glass floor, or a glass well cover.

This elegant addition serves a dual purpose: it conceals any gaskets or sealants used to secure the glass, ensuring a clean and polished look from above, while enhancing the overall aesthetic appeal of your installation.

A painted border transforms a functional safety feature into a seamless design element, perfectly complementing the surrounding floor surface and elevating the visual harmony of your space.

The painting process for our glass is meticulously executed between the layers of the laminate, a technique that prevents any wear or degradation of the finish over time. This method not only ensures durability but also adds an extra layer of protection, making the painted border resistant to scratches or fading.

However, this placement within the laminate can subtly alter the appearance of the paint colour when viewed through the thick glass. This effect is particularly noticeable with lighter shades, where the paint tends to take on a greenish tinge due to the glass’s optical properties, a natural phenomenon that adds character to the design.

For darker colours like black or anthracite grey, this tinting effect is near-zero, preserving the intended shade with striking clarity. In contrast, our example image features a light grey painted border, where both the steelwork and glass are matched to the exact same RAL colour code. Despite this , the glass border appears to contrast with the steelwork due to the greenish undertone, creating a unique visual interplay. This natural effect, while unavoidable with lighter hues, underscores the bespoke nature of our work and can be embraced as part of the design process.